The helical hydraulic rotary actuator is popular in the construction machines, agricultural machines, drilling rigs, aerial working platforms, etc. However, do you know the working principle of the hydraulic rotary actuator? How to classify the hydraulic rotary actuators? Here, we will show you the answers to these questions.

Working Principle

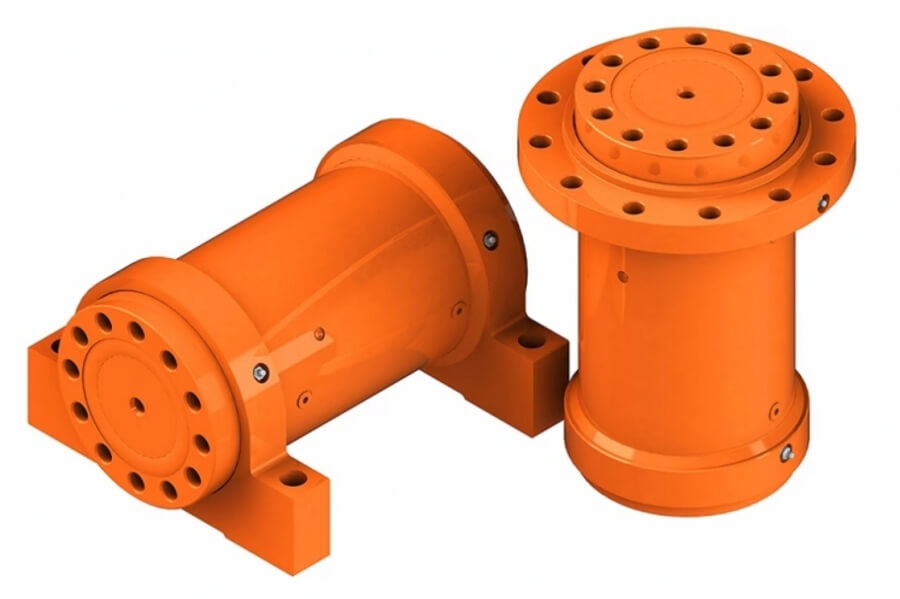

The helical hydraulic rotary actuator converts the linear motion of the piston into the oscillating motion of the output shaft through the helical thread engagement form, and its remarkable feature is its extremely high efficiency. The longer the linear motion of the piston, the greater the rotational motion. The rotary actuator is a compact assembly that combines very high torque hydraulically in a small space. Helical hydraulic rotary actuators have been successfully used in almost all applications requiring limited rotary motion and high torque. Swing rotary cylinders can also be used in very harsh conditions, underground and below 2000 meters above sea level. Oscillating cylinders are even used in the pharmaceutical and food processing industries that require high levels of cleanliness and hygiene.

Features & Advantages

Large helix angle, high torque output, high load capacity, impact resistance, zero leakage and flexible installation are realized by the most compact structure.

Applications

The swing of the working frame of the aerial work platform vehicle; the swing positioning of the drilling arm of mining equipment; the steering of tires or tracks of agricultural equipment and road equipment; the swing of actuators such as sweeper forklifts; Especially suitable for structural applications with limited installation space to realize the swing of the actuator.

Classification

The helical hydraulic rotary actuator is divided into three structural forms: rack and pinion type, blade type and spiral type. Compared with the traditional rack and pinion swing cylinder and vane type swing cylinder, helical hydraulic rotary actuator has the advantages of compact structure, small footprint, safety and reliability, maintenance-free, High pressure, no leakage, great output torque and other obvious advantages, strong power, precise positioning, easy to control.