Hydraulic rotary actuator is an important hydraulic component that uses hydraulic pressure to gather very high torque in a small space to achieve limited rotational motion. There are two commonly used rotary actuators, helical and vane. In this post, we will introduce the features and applications of the two hydraulic rotary actuators.

Working Principle

The working principle of hydraulic rotary actuator is based on hydraulic transmission and mechanical conversion. When one oil port of the hydraulic cylinder is filled with pressurized oil and the other oil port is used to return oil, the internal components (such as vanes or spiral pairs) swing under the action of pressurized oil, driving the output shaft to deflect a certain angle (usually less than 360 degrees). When the oil inlet and return ports are interchanged, the output shaft reverses.

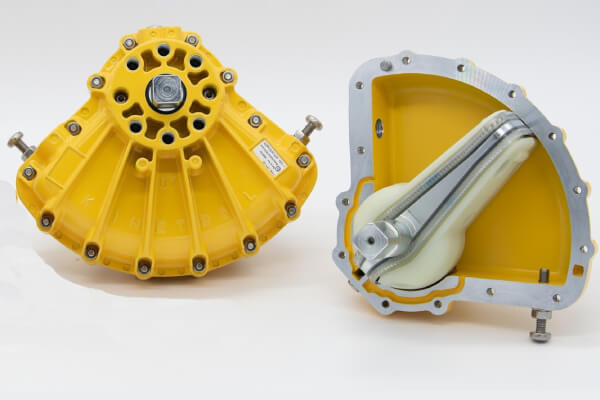

Vane-Type Hydraulic Rotary Actuator

It contains a fixed device (vane) inside, the vane section is fixed to the housing, and the piston section is fixed to the drive shaft. The output shaft rotates by the swing of the vane. It has a compact design, but the maximum rotation angle is limited.

The vane rotary actuator is mainly composed of stator block, cylinder body, swing shaft, vanes, left and right support plates and left and right cover plates. The stator block is fixed on the cylinder body, and the vanes and swing shaft are fixed together. When the two oil ports are connected with pressurized oil, the vanes drive the swin shaft to swing back and forth. According to the number of vanes, it can be divided into single-vane and multi-vane rotary actuators. The swing angle of the former generally does not exceed 280 degrees, while the swing angle of the latter is smaller, but more complex movements can be achieved through the synergy of multiple vanes.

Features

Compact structure: compact design, small footprint, suitable for installation locations where the installation location is limited.

High torque output: can generate large torque in a small volume, meeting the needs of high torque output.

Sensitive action: small moment of inertia, sensitive action, fast response speed.

Easy to control: by controlling the flow direction and flow rate of the oil, the direction and speed of rotation of the output shaft can be precisely controlled.

Strong self-lubricating ability: due to the special sealing structure of the internal blades, the rotary actuator has strong self-lubricating ability, which helps to extend the service life.

Applications

Shipbuilding industry: used to control important mechanical devices such as rudders, propellers and lifting mechanisms on large ships.

Wind power generation industry: used to adjust the angle of wind turbine blades to control output power and rotation speed.

Industrial machinery: widely used in various industrial machinery and equipment, such as excavators, bulldozers, loaders, rollers, etc.

Aerospace: plays an important role in key parts such as aircraft landing gear, brake systems and wing control systems.

Helical Hydraulic Rotary Actuator

It uses a spiral pair with a large helix angle to achieve rotational motion. The spiral rod of the output shaft is fixed to the cylinder body through a bearing, and the spiral teeth on the inner surface of the piston mesh with the spiral teeth of the spiral rod. Under the action of hydraulic pressure, the piston moves linearly and rotates along the spiral rod, thereby driving the output shaft to rotate.

Features

Helical pair design: The core component of the helical swing hydraulic cylinder is the helical pair, which consists of the helical teeth of the piston and the helical teeth of the output shaft. This design enables the hydraulic cylinder to generate a large torque in a small space.

Compact structure: Due to the use of helical pair transmission, the structure of the helical swing hydraulic cylinder is relatively compact, occupies a small space, and is suitable for occasions with limited installation positions.

High load-bearing capacity: The close meshing of the helical pair and the high material strength make the helical swing hydraulic cylinder have a high load-bearing capacity.

Large torque output: It can generate large torque in a small volume, meeting the needs of high torque output.

High-precision control: Through the advanced hydraulic control system, the output shaft rotation angle and speed can be accurately controlled.

Zero leakage: Due to the close meshing and sealing design of the spiral pair, it has the advantage of zero leakage, improving work efficiency and environmental protection performance.

Flexible installation: Its structural design makes its installation flexible and diverse, and can adapt to the needs of different working conditions and installation conditions.

Applications

Hydraulic rotary actuators are widely used in the following fields:

Aerial work platforms: used to control the swing and positioning of the work frame.

Mining equipment: such as the swing positioning of the drill arm.

Agricultural and road equipment: used for steering control of tires or tracks.

Special vehicles: such as the swing control of actuators such as sweepers and forklifts.

Garbage disposal equipment: such as the flipping of garbage cans.

At Last

Although hydraulic rotary actuators have many advantages and broad application prospects, their development also faces some technical challenges. For example, how to improve the accuracy and stability of hydraulic rotary actuators, how to reduce their manufacturing costs and energy consumption, how to adapt to more complex and changeable working environments, etc. In order to meet these challenges and promote the further development of hydraulic swing cylinder technology, it is necessary to strengthen the research on hydraulic transmission theory, optimize the structural design of hydraulic rotary actuators, improve the manufacturing process level, and develop more advanced control systems in the future. At the same time, with the continuous emergence and application of new materials and new technologies, the performance and reliability of hydraulic rotary actuators will also be further improved and perfected.