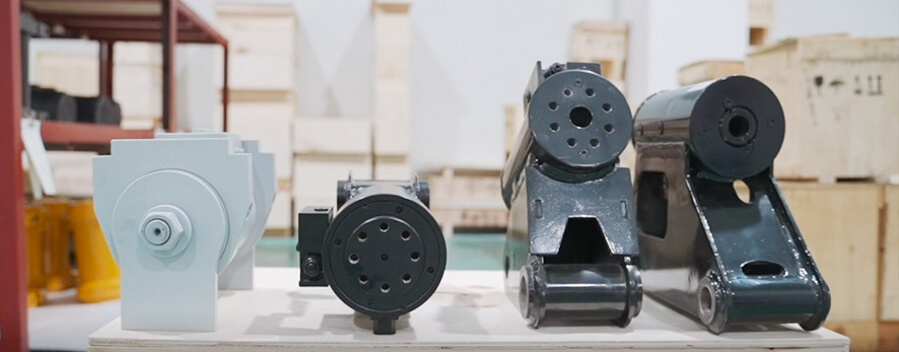

Spiral swing hydraulic cylinder is also called hydraulic rotary actuator, which has the advantages of large output torque, strong bearing capacity, small size, large swing angle, compact structure and stable operation. The processing requirements of the helical oscillating cylinder are extremely fine. Even if the processing process and the inspection and control of each link are strictly followed, the factory inspection of the finished product is also indispensable. Today we will learn about the inspection standards of the swing cylinder(helical rotary actuator).

The inspection of the swing cylinder (rotary actuator) mainly includes the following aspects:

1. Running Test: set the overflow pressure of the hydraulic station to 10Mpa, running for 10 minutes, set the overflow pressure to 21Mpa, run for 20 minutes, and check for leakage. The tested oil cylinder reciprocates more than 5 times in the full stroke under the no-load condition. Whether the output shaft of the oil cylinder moves smoothly can be seen whether the seal is damaged.

2. Starting pressure: Under the no-load condition, hydraulic oil is injected into the oil cylinder port, and the relief valve gradually increases the pressure from zero. Observe the pressure gauge and record the minimum starting pressure of the cylinder under test when starting. The starting pressure of the oil cylinder without balance valve is measured through the shell, and the starting pressure is required to be less than 2.5MPa; the starting pressure of the oil cylinder with balance valve is 1) less than 2.5MPa (connected to P1/P2 port), 2) less than 8MPa (V1/V2 port) .

3. Torque test: Add the load of the output shaft of the oil cylinder to the rated load, and observe whether the output angle of the oil cylinder can reach the rated angle.

4. Pressure test: Rotate the output shaft of the cylinder under test to both ends of the stroke respectively. Set the overflow pressure of the hydraulic station to 31MPa, keep the pressure for 10 minutes, and check for deformation and leakage.

5. Internal leakage test: Run the piston to the ends of both ends respectively, add 21Mpa pressure to the P1 oil port (P2 is opened) for 5 minutes, add 21Mpa pressure to the P2 oil port (P1 is opened) and add 21Mpa pressure to the oil port for 5 minutes minute. Check for continuous hydraulic oil flow from the port.

6. Fatigue test: Install the oil cylinder according to the customer’s application, and load the output shaft of the swing oil cylinder.

7. Load inspection (made for new products): pressurize 21Mpa, load the corresponding torque, run for 8 hours, about 2000 times.

8. Dimension inspection: check the dimensions according to the outline drawing.

9. Angle check: The total rotation angle must be 1-3° larger than the angle marked on the drawing.

10. Full stroke inspection: Make the output shaft of the cylinder under test rotate and stay at both ends of the stroke. Measure whether the total rotation angle is within the standard range used.

11. Paint inspection: Impurities or granular adhesion are not allowed; bubbles and pores are not allowed. Spray sagging and orange peel are not allowed; the color of the coating meets the requirements, and no color difference or variegation is allowed. No decoating phenomenon; insufficient spray thickness and size requirements and missing spray phenomenon are not allowed; no obvious hanger marks on the surface. Scratch the surface of the paint film with a little force with your thumbnail, and observe with the naked eye under the light that there is no scratch.

12. Surface acceptance: Check whether there are cracks or collision marks on the surface of the oil cylinder, whether there are protective sealing plates at each oil port, whether the oil port thread teeth are damaged, and perform secondary tightening on the fastening bolts.