Aerial work platforms (AWPs) are essential tools in various industries, providing workers with safe and efficient access to elevated work areas. The performance and functionality of these platforms rely heavily on the components that drive their movement and positioning. One such critical component is the hydraulic rotary actuator. This blog post explores how hydraulic rotary actuators enhance the performance of aerial work platforms, ensuring better safety, precision, and operational efficiency.

Understanding Hydraulic Rotary Actuators

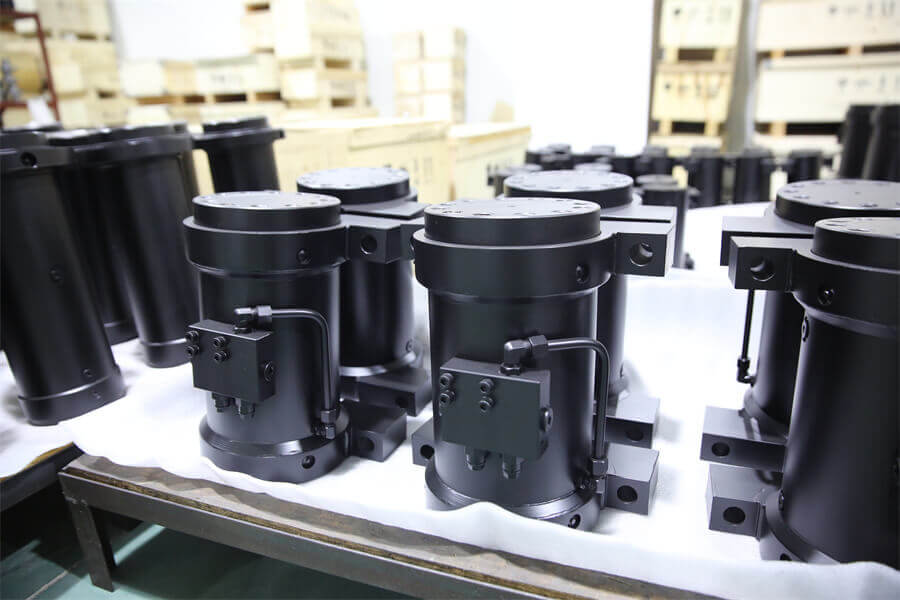

Hydraulic rotary actuators are devices that convert hydraulic energy into rotary motion. They are known for their high torque output, compact design, and the ability to provide precise control over movement. These features make them ideal for applications where space is limited, and precision is paramount, such as in aerial work platforms.

Key Benefits of Hydraulic Rotary Actuators in AWPs

1.Enhanced Precision and Control

Hydraulic rotary actuators offer exceptional control over the movement of the platform. This precision is crucial for tasks that require accurate positioning, such as maintenance, painting, or construction work at height. The smooth and controlled movement provided by these actuators minimizes the risk of accidents and improves the quality of work performed.

2.Compact Design and Space Efficiency

The compact design of hydraulic rotary actuators allows them to be integrated into the limited space available on aerial work platforms. This space efficiency is vital for maintaining the overall balance and stability of the platform while maximizing the available working area for operators.

3.High Torque Output

Aerial work platforms often need to lift heavy loads to considerable heights. Hydraulic rotary actuators deliver high torque output, ensuring that the platform can handle substantial weights without compromising on performance. This capability enhances the versatility of AWPs, making them suitable for a broader range of applications.

4.Durability and Reliability

Hydraulic rotary actuators are known for their durability and long service life. They are designed to withstand harsh working conditions, including exposure to dust, dirt, and varying weather conditions. This reliability ensures that aerial work platforms remain operational for extended periods, reducing downtime and maintenance costs.

5.Safety Improvements

Safety is a paramount concern when working at heights. The precise control and reliable performance of hydraulic rotary actuators contribute to the overall safety of aerial work platforms. By minimizing sudden movements and ensuring stable operation, these actuators help prevent accidents and injuries.

Applications in Aerial Work Platforms

Hydraulic rotary actuators are used in various components of aerial work platforms, including:

Boom Rotation: Enabling the boom to rotate smoothly and precisely, allowing operators to position themselves accurately.

Platform Leveling: Ensuring that the platform remains level regardless of the boom’s position, enhancing safety and comfort for operators.

Steering Mechanisms: Providing precise control over the platform’s movement on the ground, facilitating easy maneuverability in tight spaces.

Conclusion

Hydraulic rotary actuators play a crucial role in enhancing the performance of aerial work platforms. Their ability to provide precise control, high torque output, and reliable operation makes them indispensable in ensuring the safety, efficiency, and versatility of AWPs. As technology advances, we can expect further innovations in hydraulic actuators, leading to even more sophisticated and capable aerial work platforms.

By integrating hydraulic rotary actuators into their design, manufacturers of aerial work platforms can deliver superior products that meet the demanding needs of various industries. Whether for construction, maintenance, or any other elevated task, hydraulic rotary actuators are key to elevating performance and ensuring safe, efficient operations.