Rotary hydraulic motors are essential components in a wide range of industrial applications, playing a crucial role in converting hydraulic energy into mechanical rotational power. Their versatility, power, and durability make them a preferred choice in many sectors. Let’s explore some of the key industries where these motors are making a significant impact.

1. Construction Machinery

In the construction industry, rotary hydraulic motors are the workhorses behind the powerful movements of heavy equipment. Excavators, for instance, rely on these motors to drive the rotation of the tracks, enabling the machine to move smoothly and precisely over various terrains. The hydraulic motor provides the necessary torque and speed control, allowing the operator to navigate the excavator with ease during digging and earthmoving operations.

Similarly, in loaders, rotary hydraulic motors are used to power the lifting and tilting mechanisms. They can handle heavy loads with high efficiency, ensuring that materials can be quickly and accurately positioned. The ability of these motors to provide consistent power even in harsh working conditions, such as on construction sites with dirt, debris, and varying slopes, makes them indispensable in the construction machinery sector.

2. Agricultural Machinery

The agricultural industry also benefits greatly from the use of rotary hydraulic motors. Tractors, which are the backbone of modern farming, use these motors for a variety of functions. They power the wheels, enabling the tractor to move across fields with different soil conditions. Additionally, rotary hydraulic motors are used in the operation of implements attached to the tractor, such as plows, harrows, and seeders.

Harvesters, another important piece of agricultural equipment, rely on rotary hydraulic motors for their complex movements. These motors control the rotation and movement of the cutting mechanisms, ensuring that crops are harvested efficiently and with minimal damage. The precision and power provided by hydraulic motors are crucial in meeting the demands of modern agriculture, where high productivity and quality are essential.

3. Industrial Manufacturing

In the industrial manufacturing setting, rotary hydraulic motors are used in a multitude of applications. Conveyor systems, for example, often use these motors to drive the rollers, ensuring the smooth and continuous movement of materials along the production line. The ability to control the speed and torque of the motors allows for precise adjustment of the conveyor speed, depending on the production requirements.

Presses, used in metalworking and other manufacturing processes, also utilize rotary hydraulic motors. They provide the force needed to shape and form materials with high accuracy. The hydraulic motor’s ability to deliver consistent power and withstand heavy loads makes it ideal for applications where high pressure is required, such as in stamping and forging operations.

4. Material Handling Equipment

Material handling is another area where rotary hydraulic motors shine. Forklifts use these motors to power the lifting and tilting of the forks, allowing for the safe and efficient handling of heavy loads. The motors can quickly respond to the operator’s commands, ensuring smooth and precise movements during loading and unloading operations.

In addition, cranes and hoists also rely on rotary hydraulic motors for their lifting and rotating functions. These motors provide the necessary power and control to lift heavy objects and position them accurately in three-dimensional space. Their reliability and durability are essential in ensuring the safety and efficiency of material handling operations in warehouses, construction sites, and other industrial settings.

5. Marine and Offshore Industries

In the marine and offshore sectors, rotary hydraulic motors are used in a variety of applications. On ships, they are used to drive the propellers, providing the thrust needed for the vessel to move through the water. The ability of these motors to handle the high-power requirements and the harsh marine environment makes them a crucial component in ship propulsion systems.

Offshore platforms also use rotary hydraulic motors for various operations, such as drilling and lifting. They can operate reliably in the salty and corrosive marine environment, providing the power and control needed for these critical operations. The durability and resistance to wear and tear of hydraulic motors make them well-suited for the demanding conditions of the marine and offshore industries.

6. Mining Industry

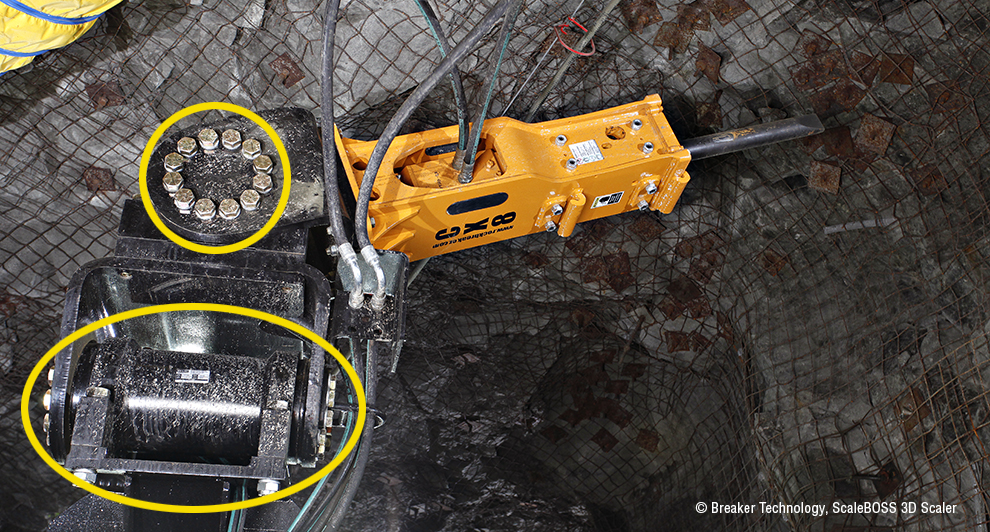

The mining industry is another heavy-duty sector that relies on rotary hydraulic motors. In mining equipment such as drills, crushers, and conveyor systems, these motors provide the power and torque needed to handle the tough mining operations. They can operate in dusty, dirty, and often harsh underground or open-pit mining environments, withstanding the vibrations and heavy loads associated with mining activities.

For example, in a mine conveyor system, rotary hydraulic motors ensure the continuous movement of ore and waste materials, even under heavy loads and over long distances. The motors can be easily integrated into the mining machinery’s hydraulic system, providing reliable and efficient operation for the entire mining process.

In Conclusion

Rotary hydraulic motors have a wide range of applications across different industries. Their ability to provide high power, precise control, and reliable operation in various working conditions makes them an essential component in many types of machinery and equipment. As technology continues to advance, we can expect further improvements and innovations in rotary hydraulic motor design, leading to even more efficient and versatile applications in the future. Whether it’s in construction, agriculture, manufacturing, or other industries, these motors will continue to play a crucial role in driving productivity and performance. Understanding their applications and capabilities is key for engineers, technicians, and industry professionals to make informed decisions and optimize the use of these powerful hydraulic components.