In the world of industrial automation and machinery, choosing the right actuation system is crucial for ensuring optimal performance, efficiency, and reliability. Among the various options available, hydraulic helical rotary actuators stand out due to their unique advantages. These actuators are known for their ability to deliver high torque in a compact design, making them an ideal choice for a wide range of applications. In this blog post, we’ll explore the key advantages of hydraulic helical rotary actuators compared to other actuation systems.

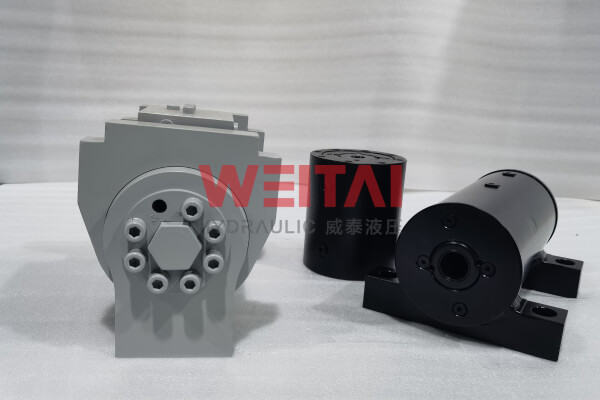

I. High Torque Output in a Compact Design

One of the most significant advantages of hydraulic helical rotary actuators is their ability to produce high torque output within a compact design. The helical gearing mechanism allows for the generation of substantial torque while maintaining a relatively small footprint. This compactness is particularly beneficial in applications where space is limited, such as in mobile equipment, industrial robots, and heavy machinery.

Comparison:

- Electric Actuators: While electric actuators can provide precision, they typically require larger motors or gearboxes to achieve high torque, which increases the overall size and weight of the system.

- Pneumatic Actuators: Pneumatic systems often require larger cylinders to generate comparable torque, resulting in a bulkier design that may not be suitable for space-constrained environments.

II. Smooth and Precise Rotary Motion

Hydraulic helical rotary actuators excel in delivering smooth and precise rotary motion, which is essential in applications that demand accurate positioning and control. The helical gearing mechanism ensures that the rotation is continuous and free of jerks, providing consistent performance even under varying loads.

Comparison:

- Electric Actuators: Electric actuators offer good precision but may struggle with smoothness at low speeds or under fluctuating loads, leading to potential issues with positioning accuracy.

- Pneumatic Actuators: Pneumatic actuators can be less precise due to the compressibility of air, which can lead to variations in positioning and motion control.

III. Durability and Reliability in Harsh Environments

Hydraulic helical rotary actuators are known for their durability and reliability, especially in harsh environments where other systems might fail. These actuators are designed to withstand extreme temperatures, heavy loads, and continuous operation, making them ideal for applications in construction, mining, and offshore industries.

Comparison:

- Electric Actuators: Electric systems are sensitive to environmental factors like dust, moisture, and temperature extremes, which can compromise their reliability in harsh conditions.

- Pneumatic Actuators: While pneumatic actuators can operate in challenging environments, they may suffer from wear and tear due to the abrasive nature of compressed air, especially if the air is not adequately filtered and lubricated.

IV. High Power Density

The power density of hydraulic helical rotary actuators is another key advantage, meaning they can generate a large amount of power relative to their size and weight. This high power density enables these actuators to perform heavy-duty tasks with minimal physical space, making them ideal for compact machinery that requires significant force.

Comparison:

- Electric Actuators: Electric actuators tend to have lower power density compared to hydraulic systems, requiring larger components to achieve the same level of performance.

- Pneumatic Actuators: Pneumatic actuators have lower power density due to the limitations of compressed air as a power source, often requiring larger actuators to achieve the same force.

V. Ability to Handle High Loads and Shock Loads

Hydraulic helical rotary actuators are well-suited for applications that involve high loads and shock loads. Their robust design allows them to absorb and dissipate energy efficiently, reducing the risk of damage and ensuring continuous operation even under demanding conditions.

Comparison:

- Electric Actuators: Electric systems may struggle with high shock loads, leading to potential damage to motors or gearboxes.

- Pneumatic Actuators: Pneumatic actuators are less capable of handling high shock loads, as the compressibility of air can lead to inconsistent force application.

VI. Flexibility in Force and Speed Control

Hydraulic helical rotary actuators offer excellent flexibility in controlling both force and speed, allowing for precise adjustments based on the requirements of the application. The hydraulic fluid flow and pressure can be easily regulated to achieve the desired performance characteristics.

Comparison:

- Electric Actuators: While electric actuators offer precise speed control, they may require complex and expensive control systems to match the flexibility of hydraulic systems.

- Pneumatic Actuators: Pneumatic actuators offer less control over force and speed, with adjustments often limited to changing air pressure or flow rates, which may not provide the same level of precision.

VII. Longer Operational Life with Minimal Maintenance

The design of hydraulic helical rotary actuators is inherently robust, leading to a longer operational life with minimal maintenance requirements. These actuators are built to handle continuous operation and resist wear and tear, reducing the need for frequent repairs or replacements.

Comparison:

- Electric Actuators: Electric systems often require regular maintenance, including motor inspections, gearbox lubrication, and component replacements, to ensure reliable operation.

- Pneumatic Actuators: Pneumatic actuators require regular maintenance to prevent issues like air leaks, contamination, and component wear, which can affect performance over time.

Conclusion

Hydraulic helical rotary actuators offer a unique combination of high torque, precision, durability, and flexibility that makes them superior to many other actuation systems in a variety of applications. Whether in harsh environments, compact spaces, or heavy-duty tasks, these actuators deliver reliable performance with minimal maintenance. By understanding the advantages of hydraulic helical rotary actuators, engineers and industry professionals can make informed decisions that enhance the efficiency and effectiveness of their machinery.

As industries continue to evolve, the demand for robust, efficient, and reliable actuation systems will only grow, making hydraulic helical rotary actuators a critical component in the future of industrial automation and machinery.