SUMMARY

Hydraulic rotary actuators are one of the most widely used actuators in industrial automation. They are widely used in applications such as mechanical presses, cranes, injection molding machines, oil and gas production equipment, and automotive manufacturing. With its high accuracy, reliability, and power, the hydraulic rotary actuator is a major driving force in the industry.

Today we are talking about 8 tips to master rotary drives.

1 Working principle of the rotary actuator

Hydraulic rotary actuators work by using the force of hydraulic pressure to move a piston. The hydraulic pressure is generated by a hydraulic pump, and it is then transmitted through the control valve and into the cylinder. The piston inside the cylinder then moves in either direction, depending on the direction of the hydraulic pressure.

The speed of the actuator is determined by the pressure of the hydraulic pump, and the force of the actuator can be adjusted by varying the pressure of the pump. The control valve can also be used to adjust the direction of the actuator, allowing it to move in either direction.

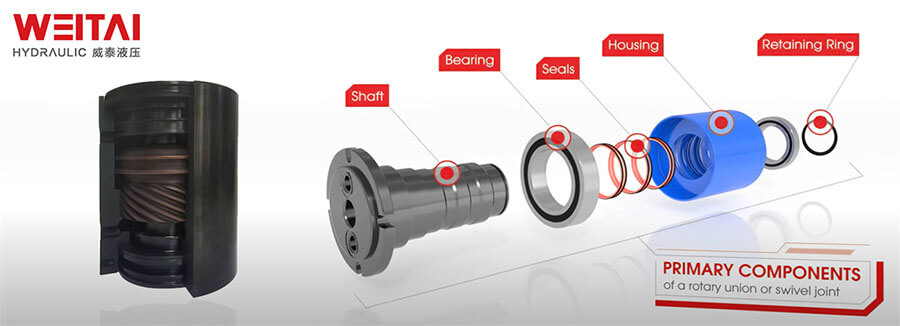

2 Rotary actuator components

A hydraulic rotary actuator typically consists of three main components: a cylinder, a piston, and a rotary gear. The cylinder is the outermost component and houses the piston and the rotary gear. The piston is connected to the rotary gear which is driven by hydraulic pressure. The pressure is created when a fluid, usually oil, is forced into the cylinder under pressure. The pressure moves the piston, which in turn rotates the rotary gear, providing the required rotary motion to move a load.

3 How to make the rotary actuators

A hydraulic rotary actuator is a device that converts hydraulic energy into mechanical energy. It is used in a wide variety of industrial applications. The manufacturing process of a hydraulic rotary unit involves several steps, starting with the selection of materials. After the materials are chosen, they are cut, bent, and formed into the necessary shapes to create the necessary components. These components are then welded, machined, and assembled into the finished product. Finally, the actuator is tested to ensure that it meets the necessary specifications. The entire process is complex and requires the use of specialized equipment and skilled technicians in order to ensure that the product meets all quality requirements.

Follow WEITAI Hydraulic to have a factory tour to know how to make rotary actuators!

4 The importance of cylinder sealing

With the help of rotary cylinders, we can accomplish different tasks. However, if you want to ensure the normal generation of pressure, the prerequisite is to ensure tightness. This shows the importance of the sealing ring in the rotary cylinder.

If the sealing of the hydraulic rotary cylinder is poor, not only will the effect not be achieved during the energy conversion process, but it will also cause serious waste.

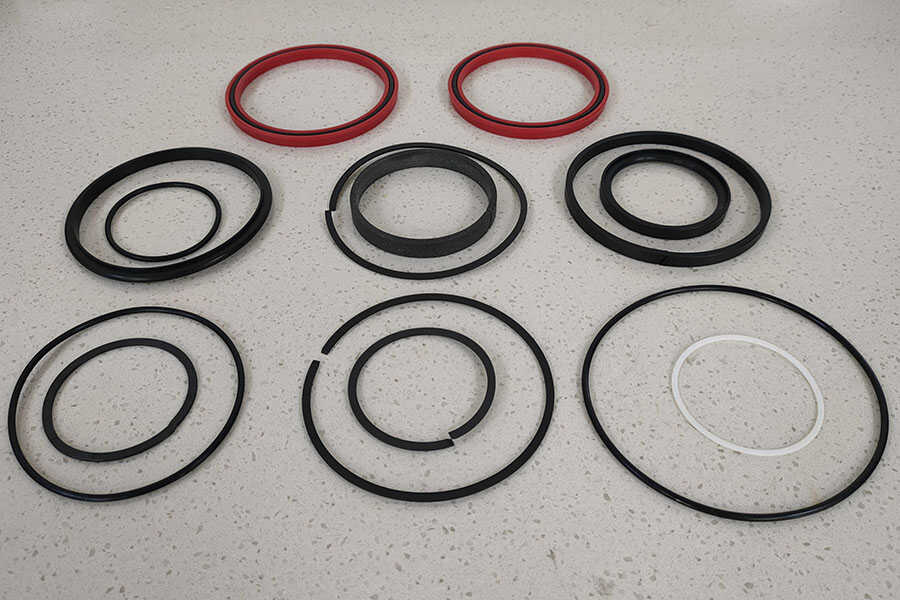

To prevent leakage of hydraulic oil, we will install a sealing ring between the cylinder barrel and the piston. In addition, corresponding sealing rings need to be installed between the cylinder barrel and the end caps, between the piston rod and the guide sleeve, and between the piston rod and the cylinder head.

Not only does a guide sleeve need to be installed between the front end of the hydraulic cylinder and the piston rod, but also a corresponding dust-proof ring should be equipped. These sealing devices are the parts that effectively guarantee their sealing. The sealing ring is usually an annular cover composed of one or several parts. We can fix it on a ring or washer of the bearing so that it can be tightly combined with other rings or washers to prevent the leakage of lubricating oil and Foreign object intrusion.

When we choose the sealing ring, we should ensure its quality. Otherwise, it is not only difficult to ensure the sealing but also cannot guarantee the normal performance of our hydraulic cylinders.

In the process of daily use of hydraulic cylinders, it is necessary to check the sealing ring. If any wear is found, it should be replaced in time to prevent the operation of the hydraulic cylinder from being blocked due to oil leakage, and its effectiveness cannot be exerted.

5 Application of rotary actuator

Hydraulic rotary actuators are widely used in a variety of industrial applications. They are commonly used in mechanical presses, cranes, injection molding machines, oil and gas production equipment, and automotive manufacturing.

In the automotive industry, hydraulic rotary actuators are used to control brakes, suspension, and steering systems. They are also used in agricultural equipment, such as tractors, combines, and harvesters.

In addition, helical rotary actuators are also used in a variety of robotic applications. They can be used to control the movement of robotic arms and other robotic components.

6 Factors Affecting Cylinder Quality

The material quality of the oil cylinder is an important factor affecting the quality of the oil cylinder, and the processing technology and material properties will also affect the durability of the oil cylinder. The quality of oil cylinders with different welding processes will also be different. For example, different welding processes such as CO2-shielded welding and argon arc welding will affect the strength and durability of the oil cylinder. The correct assembly process can ensure the strength and durability of the oil cylinder. The surface treatment of the oil cylinder is also one of the important factors affecting the quality of the oil cylinder. Different surface treatment processes such as painting, oxidation, and coating can improve the corrosion resistance and wear resistance of the oil cylinder, thereby improving the quality of the oil cylinder. Strict inspection of the oil cylinder can ensure that the oil cylinder can meet the design requirements, thereby improving the quality of the oil cylinder.

7 Precautions for the use of rotary actuators in construction machinery

Under normal circumstances, when construction machinery is working, the hydraulic system of the construction hydraulic cylinder generates a lot of heat due to various pressure losses, which makes the temperature of the hydraulic oil in the system rise, and the hydraulic oil is easy to oxidize when the system temperature is too high. After oxidation, organic acids will be generated, which will corrode metal components, and will also generate colloidal deposits that are insoluble in oil, which will increase the viscosity of hydraulic oil and deteriorate the anti-wear performance. Therefore, hydraulic cylinders should be placed in a stable, clean, and ventilated environment to prevent pollution, corrosion, and moisture. After the installation is completed, a test should be carried out to ensure the normal operation of the cylinder. The operation of the hydraulic cylinder must be safe and must not be overloaded to avoid damage. Regularly check the normal working status of the cylinder and whether the components are damaged, and find out the problem in time and deal with it in time. Regularly change the lubricating oil to maintain the normal operation of the hydraulic cylinder. If abnormal conditions such as excessive temperature and oil leakage of the hydraulic cylinder are found, stop using it in time, and repair and replace it in time.

8 How to choose a qualified rotary actuator

When selecting a hydraulic rotary cylinder, it is important to consider the pressure requirements, the maximum load capacity, the speed of the cylinder, the type of mount, and the environment in which the cylinder will be used. It is also important to consider the stroke length, the type of fluid the cylinder will be using, and the type of seal that is required. Finally, it is important to consider the cost and the quality of the cylinder.

WEITAI Hydraulic, the top manufacturer of rotary actuators from China, provides High torque, high bearing capacity, and high power density rotary actuators. Zero internal leakages, moving parts enclosed, and smooth operation make the actuators suitable for tight spaces and harsh environments.

WEITAI Marketing Department